PRODUCTS

A battery ecosystem for the 21st century.

We’ve re-engineered the battery from the ground up to provide practical solutions to the industry’s toughest challenges. The 24M technology suite empowers you to build a better battery and pave the way to a greener future.

A new era of energy storage.

Transformative.

Battery fires. Range anxiety. High costs. Recyclability. These decades-old roadblocks continue to stall growth in the battery industry. The 24M battery technology suite targets these challenges to drive the market forward.

Flexible.

The 24M technology portfolio provides flexibility for cell manufacturers, allowing individual technologies to be integrated into conventional manufacturing platforms for select benefits — or combined to unlock even greater potential.

Versatile.

From standard lithium-ion to lithium-metal and sodium-ion, 24M’s battery technologies aren’t limited to just one battery product or chemistry. This versatility allows manufacturers to tailor solutions to a broad array of energy storage demands.

Unlock a spectrum of benefits.

Target specific challenges with individual solutions, or combine them all to build a battery that redefines energy possibilities.

The 24M battery technology suite.

With 24M, you can mix and match processes and products to meet your exact needs. Explore our full technology portfolio:

IMPERVIO

Redefine battery safety.

Prevent catastrophic fires and eliminate mass recalls with Impervio, our transformative separator technology that suppresses dendrite formation and detects potential shorts before they occur.

ETERNALYTE

Upgrade your battery.

The next-generation Eternalyte electrolyte enables significant improvements in safety, cycle life, rate capability, fast charge rates and low-temperature performance, regardless of chemistry.

24M ETOP

Maximize energy density.

24M ETOP pack design features electrodes packaged directly into the battery pack, eliminating unnecessary materials while achieving the highest pack energy density available.

Connect with us.

Got questions? Get in touch with the 24M team.

LIFOREVER

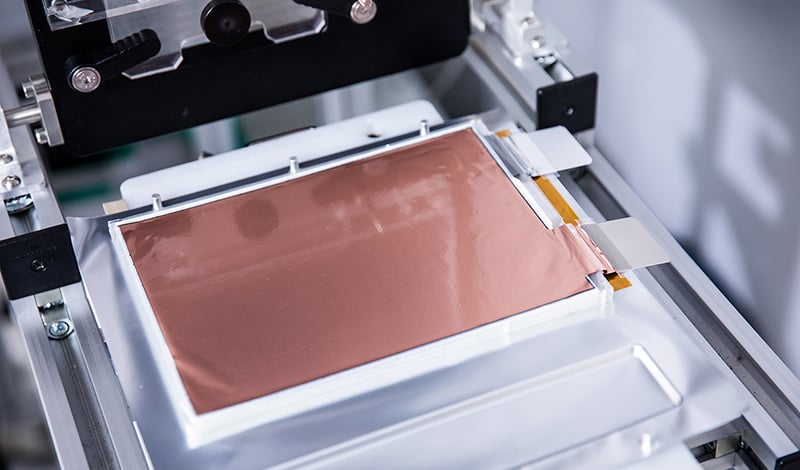

Revolutionize cell design.

The unique, binderless design of LiForever cells streamlines battery construction, improves performance and dramatically enhances recycling and reuse of materials.

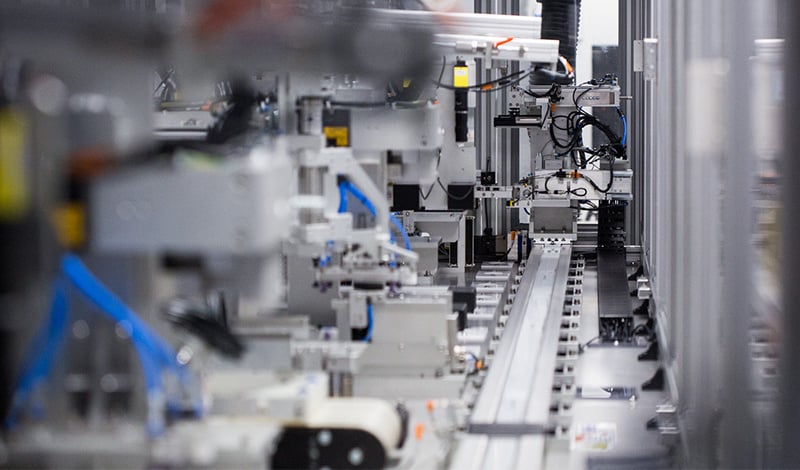

24M EQUIPMENT

Cut costs and increase efficiency.

Our manufacturing process eliminates half the steps of conventional lithium-ion battery production, making battery production simpler, safer and more sustainable.

Get in touch.